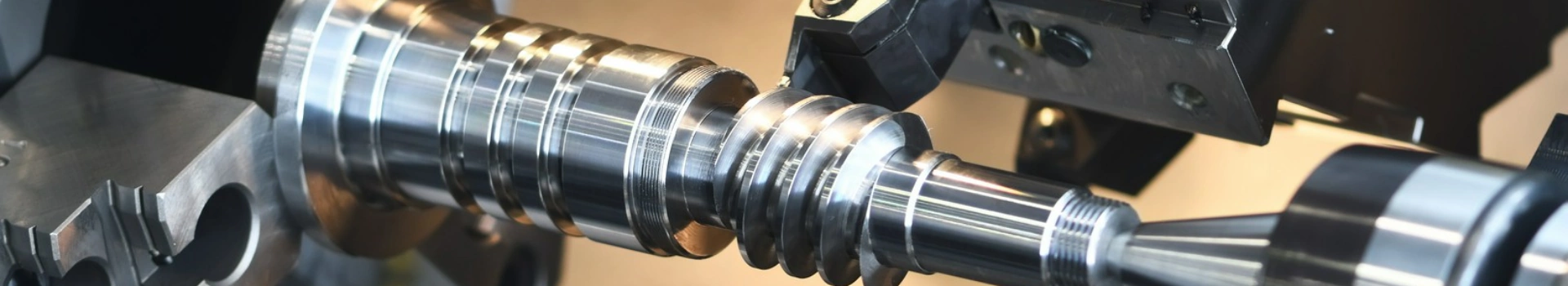

Toczenie CNC

Firma posiada rozbudowany park maszynowy którego znaczną część stanowią tokarki CNC. Toczenie CNC wykonujemy zarówno dla ilości seryjnych ale także dla pojedynczych detali. Toczymy detale od kilku milimetrów średnicy nawet do 700mm a długość jaką możemy obrabiać sięga 3000mm.

Posiadamy m.in. nowoczesne 4-osiowe centrum tokarskie dzięki czemu możemy uzyskać wysoką powtarzalność i dokładność obrabianych elementów przy zachowaniu niskiej chropowatości powierzchni. Dodatkowym atutem jest także możliwość wykonywania na tej maszynie operacji frezarskich i wiertarskich dzięki dodatkowej osi Y oraz napędzanym narzędziom.

Wszystko to pozwala na eliminację, w wielu przypadkach, dodatkowych czynności do tej pory wykonywanych na innych obrabiarkach jak szlifierki, frezarki czy wiertarki. Ma to wpływ nie tylko na koszty wykonania gotowego detalu ale co jest ważniejsze skraca cykl produkcyjny i minimalizuje możliwość produkcji wadliwych części.

Współpracujemy z Klientami w całej Polsce. Gotowe detale wysyłamy za pośrednictwem firm kurierskich oraz spedycyjnych, a także dostarczamy produkty za pośrednictwem własnego transportu.

Zapraszamy do przesyłania detali do wyceny

Toczenie CNC jest to rodzaj obróbki ubytkowej w większości stosowany do obróbki detali na bazie brył obrotowych. Istnieje możliwość obróbki także elementów o nieregularnych kształtach jak odlewy oraz odkuwki.

Nowoczesne toczenie CNC charakteryzuje się wysoką dokładnością oraz powtarzalnością procesu obróbki, a także niską chropowatością uzyskiwanych powierzchni. Wszystko to przy zachowaniu wysokiej wydajności, na którą ma bez wątpienia duży wpływ skoncentrowanie obróbki wykorzystując narzędzia napędzane, dodatkowe osie sterowane czy dodatkowe suporty narzędziowe i wrzeciona.

Toczenie CNC jest częścią skomputeryzowanego procesu wytwarzania obejmującego projektowanie wspomagane komputerowo (CAD) oraz przetwarzanie modelu 3D na program sterowania pracą obrabiarki (CAM).